MKB Metallguss GmbH

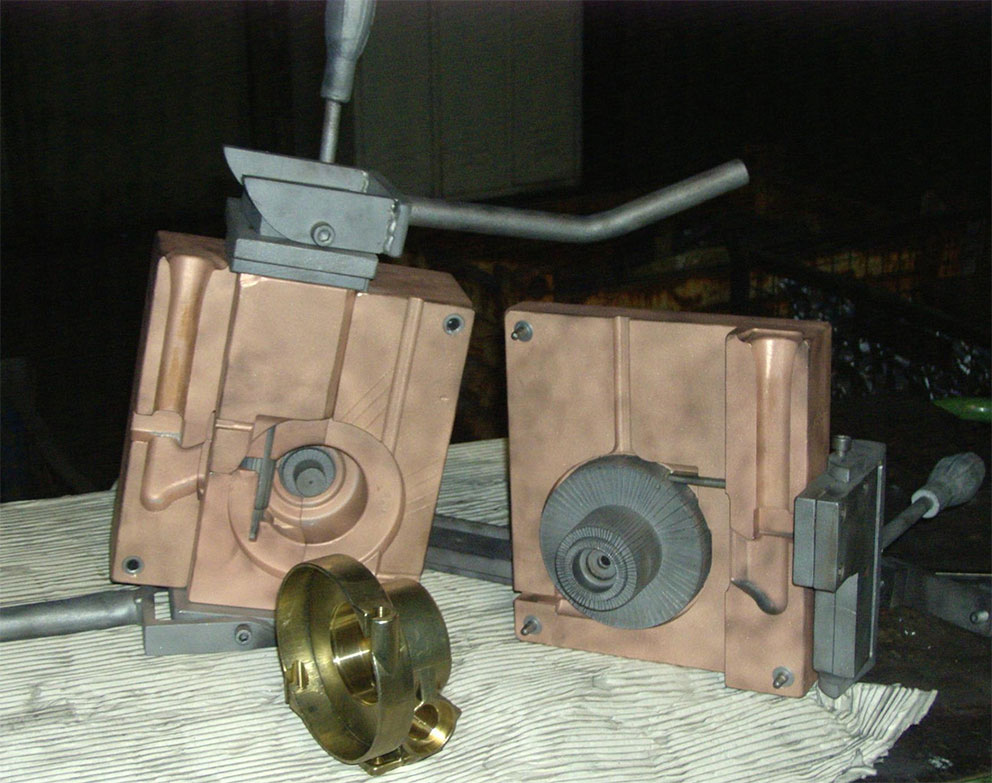

Gravity Die Casting

Even raw casting can be precise

Even in raw casting, our gravity die casting process is superior to many other moulding processes,

Even in raw casting, our gravity die casting process is superior to many other moulding processes,

- All raw cast parts are manufactured with high accuracy according to DIN EN ISO 8062-3

- Copper alloys are cast according to EN 1982 or as a special MKB alloy

- Aluminium alloys are cast according to EN 1706

- Permanent batch-related monitoring by means of spectral analysis guarantees exact adherence to standard values and required strength values

- High precision, many years of experience and intensive advice right from the design phase combine to guarantee long-term, reproducible quality

Gravity die casting in comparison

vs. welded designs:

- Mechanical processing can often be dispensed with, as the contours are manufactured true to the design contours

- Cost savings from an economical quantity

- Diverse designs, economically feasible

- Pre-cast bores (round hole, slot variants)

- Material savings

- More rigid construction due to cost-effective stiffening ribs and radii

- No "weld weak spot"

- Current resistance at the weld seam is eliminated

Gravity die casting in comparison

vs. investment casting:

- Expensive tight investment casting tolerances are often not required for the application, gravity die casting has advantages here

- Lower tool costs

- Shorter delivery times

Gravity die casting in comparison

vs. complete mechanical processing:

- Serious cost savings from economic lot sizes

- No high material losses

- Short processing machine run times

Gravity die casting in comparison

vs. sand casting:

- Better electrical conductivity with copper alloys

- Less expensive manufacturing process

- Tighter tolerances and better surfaces

- The risk of the melt absorbing gas from the moulding material is eliminated

- Mechanical processing is often no longer necessary

Gravity die casting in comparison

vs. pressure die-casting:

- Shorter delivery times

- Significantly lower tool costs

- Small batch sizes can also be produced economically

- Weldability with aluminium alloys

- Undercuts and cavities possible

Contact

Tobias Koderer

Leiter Vertrieb / Marketing

Jetzt unverbindlich anfragen und beraten lassen.

Contact +49 (0) 8421 - 98 89 89

E-Mail: mkb@m-k-b.de

Terminvereinbarung

Gerne beraten wir Sie - vereinbaren Sie einen Termin